Matson Navigation Co.

2. STARSHINE Design on Matson Time

As indicated in an earlier post (click here and scroll down to “2. Sinking Beer Cans”), my buddy Doug and I both worked for Matson Navigation Company in their Industrial Engineering Department. This enabled us to plan our restoration of the GAMBELLA in detail on company time. Eventually, however, Doug got ambitions to build a much larger boat, and I bought out his share of the GAMBELLA to help finance his efforts in that regard.

Doug had two main criteria for his new boat. He wanted it to have a flush deck with no visible cabin, and he wanted it to have full headroom below for himself. Doug was about a half inch taller than me — almost six foot three inches. So that, together with the flush deck requirement, dictated a design for a rather large boat. The STARSHINE, as she was eventually named, measured fifty-six feet on deck.

Doug was intent on designing and building this boat himself. In designing a vessel, making a drawing or even a scale model, may be the easy part. The problem is that a considerable error in measurements can accumulate in scaling up the plan. The traditional way to avoid this error is to lay out the curves full size on a large floor of some kind. Spaces used for this process were often lofts; hence the practice became known as lofting.

Doug didn’t have access to a loft, but he did have access to the office computer and he was a math major in college. Using a computer-aided process called multiple regression analysis, he managed to fit a mathematical equation to each longitudinal and each cross-section line of his plan. He then set them equal to each other at every place they were supposed to cross to see if they actually did meet at that point. If they didn’t, he modified the equations until they did. Even with the aid of the computer it was a long process that went on for weeks. This was in the early days of office computer systems. The individual terminals were like teletype machines and they all accessed a central processor. The engineers in the department all had their own offices and there was no office network to speak of and, hence, no central oversight on the computer use. If you could hear a terminal running then that engineer was obviously hard at work. I was the only one who knew what Doug was doing and I kept mum about it. Doug also got enough of his assigned work done that no one got suspicious. I left the company to go to work for the Maritime Administration before he finished, but he finally did get it all done. It was quite an impressive effort and everybody thought he worked so hard for Matson.

1. Working for Matson

Toward the end of my active duty with the Navy I began to think about what I was going to do with the rest of my life. I went to job interviews at a number of firms in the San Francisco Bay Area, and finally ended up with Matson Terminals, a subsidiary of the steamship operator Matson Navigation Company. Matson Terminals was a stevedore firm (loading and discharging of vessels) and they were the only company I talked to that placed some significance on my Navy experience aboard a cargo vessel. The parent company was mainly involved with interstate commerce, primarily to and from Hawaii and the West Coast, but also Guam and other Pacific territories. Matson Terminals was the stevedore for the parent company, but also had other “outside” customers as well. The Vietnam war was heating up at the time and Matson Terminals had the contract to do all the stevedore work for the Oakland Army Terminal. The Army Terminal was all conventional cargo, but Matson, in general, was a pioneer on the West Coast for containerized cargo traffic. At the time there was only one container crane in the SF Bay Area and that was in Alameda, next to the Dole Pineapple warehouses, one of Matson’s big customers. Now, If you drive through the Port of Oakland, for instance, you can see container canes from horizon to horizon.

I had a split tour with Matson, working for Terminals for two years before trying my hand at the electronics industry in Silicon Valley for a couple of years. Then it was back to the parent company Matson Navigation for another four years. My combined tenure with Matson was in their Industrial Engineering Department. In general, the work was not very exciting or creative. It was usually, “fix this problem here” or “come up with a solution to that problem there.”

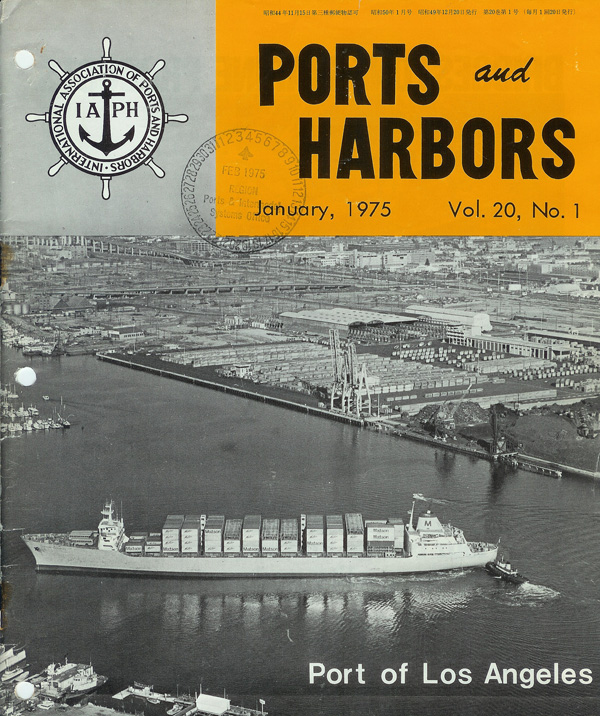

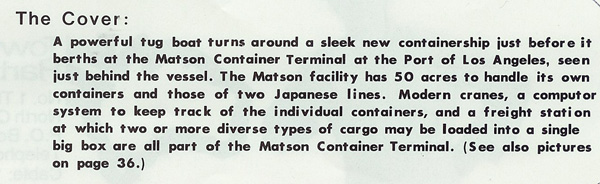

There was, however, one project that I remember distinctly as being quite satisfying from start to finish. It was the design and construction of a brand-new container terminal in the Port of Los Angels starting with approximately fifty acres of vacant land and ending with a state-of-art container terminal. As I remember, the project ran on for well over a year and I was the principal engineer for Matson in charge of the conceptual design. I had to deal regularly with the civil engineers at the Port of Los Angeles who did the detailed “stress and strain” work. I became a regular commuter between SF and LA, sometimes flying back and forth two, or even three times, a week. I was very proud of the final result. It was impressive, and I remember thinking “This is without a doubt the best marine container terminal in the world.” It did make the industry news worldwide. Here are two aerial photographs of the completed terminal:

Categories

- THE GALLERY

- Uncle Rob's Art

- 3D Works (stills) I

- 3D Works (stills) II

- 3D Works (stills) III

- 3D Works (video)

- Design & Abstract I

- Design & Abstract II

- Design & Abstract III

- Figurative Works I

- Figurative Works II

- Landscapes I

- Landscapes II

- Largest Art Project

- Nautical and Marine Images (video)

- Nautical and Marine Images I

- Nautical and Marine Images II

- Nautical and Marine Images III

- Nautical and Marine Images IV

- Portraits

- Still Life Images

- Stump Hollow Photo Essay I

- Stump Hollow Photo Essay II

- Uncle Rob's Mendocino Shop

- The Five Sense Series

- Irene's Creations

- Works by Don Mason

- Works by Don Mason II

- Works by Joseph de Borde

- Painting by Albert Robbins

- Art by Leslie Masters Villani

- Paintings by Nellie Harriet Parker

- The Art of Bee Yearian

- Works by Evie Wilson

- Uncle Rob's Art

- SCHOONER MOON BOOKS

- SEA STORIES

- ONE DOZEN AND TWO ESSAYS

- Cousinhood

- Art by Definition

- Cake Mixed Economy

- Marriage Anyone?

- Sex and/or Violence

- Searching for Truth

- The Philosophical Roots of Science

- Stepping Stones and Stumbling Blocks

- On Being Good

- Teaching By Example

- The Basic Law of Civilization

- Where Goeth Evil?

- A Modern Empircal "Religion"

- Knowledge as Wealth

- PAPERS AND ARTICLES

- FAMILY STORIES

- BOOK REVIEWS

Archive

- December 2021

- October 2020

- June 2020

- September 2019

- July 2017

- March 2017

- December 2016

- November 2016

- October 2016

- August 2016

- July 2016

- June 2016

- May 2016

- March 2016

- February 2016

- February 2015

- January 2015

- February 2014

- December 2013

- November 2013

- August 2013

- June 2013

- August 2012

- July 2012

- April 2012

- March 2012

- February 2012

- November 2011

- September 2011

- June 2011

- May 2011

- April 2011

- March 2011

- February 2011

- January 2011

- December 2010

- November 2010

- October 2010

- September 2010

- August 2010

- July 2010

- June 2010

- May 2010

- April 2010

- March 2010

- February 2010

- January 2010

- December 2009

- November 2009

- October 2009

- September 2009

- August 2009

- July 2009

- June 2009

- May 2009

- April 2009

- March 2009

- February 2009

- January 2009

- December 2008

- November 2008

- October 2008

- September 2008